Operator station

Operator station

Close-up of display

Close-up of display

The contoured dash has clean, attractive styling and ergonomic controls for easy use:

- Controls are color coded and labeled with English words for easy identification by the operator.

- Controls are logically placed and easy to reach.

- The power take-off (PTO) switch allows the operator to get fingers underneath it, like a T-handle, to pull up for easy activation.

- The reverse implement option (RIO) switch is a yellow button.

- The latch control on foot-lift models and hydraulic-lift control on power-lift models and the park brake latch are pivot levers for low effort.

- Cruise control activation is handled by an automotive-style button.

- Separate engine speed and choke controls make starting and warming up the engine easier in cold weather.

- The choke lever is spring loaded to eliminate the chance the tractor will be unintentionally operated with the choke partially closed.

Display panel

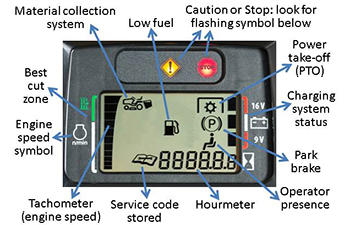

X350R display panel with indicators identified

X350R display panel with indicators identified

Display has the look and feel of a modern automobile. A power-up sequence cycles lights and gauges to indicate they are working:

- Display features dark-cockpit design to minimize operator distractions.

- Display is back lit for night visibility.

- Night visibility is especially useful with snow blower use.

- When the hopper is full, the hopper-full light comes on and a buzzer sounds. The operator needs to manually shut off the PTO.

- Hour meter makes it easy to tell when oil changes and other maintenance should be performed.

- Low-fuel light provides the operator with a noticeable warning when low on fuel.

- A tachometer graphically displays engine speed.

- Target-zone graphics inform the operator of the engine speed range to use for best cut quality.

- An indicator tells the operator when the PTO is operating.

- Bright caution and stop lights capture the operator's attention when important information is on the instrument cluster.

- Damage can be prevented and repair costs can be reduced by addressing problems early.

- Operators are advised of what the problem is if they attempt to operate the mower with unsatisfied PTO, seat, or park brake interlocks.

- The indicators are also useful to identify the reasons the PTO or engine may have shut off when an interlock is unsatisfied.

- Operators are advised if battery voltage is low, normal, or excessive.

- The service indicator light illuminates to indicate a diagnostic error code is stored.

- On-board diagnostics provides trouble codes for use by trained technicians.

- For example, a technician can test switch functionality and circuit continuity without tools.

Twin Touch™ foot control

Twin Touch foot control

Twin Touch foot control

Cruise control

Cruise control

Twin Touch foot pedals control the speed and direction of travel:

- Automotive-type accelerator control ensures easy operation.

- Operator can change direction without lifting foot off the platform.

- Large pedal surface gives superior operator comfort.

Cruise control

Cruise control is standard equipment:

- To engage, push the cruise-control button and hold until the foot is removed from the forward pedal.

- For emergency stop, the cruise control can be released by pushing on the brake pedal or the forward pedal.

Mower deck height adjustment

Onboard mower adjusting gauge and wrench

Onboard mower adjusting gauge and wrench

Rotary dial knob makes adjusting mower cut height quick and easy:

- Provides mower cut heights in 0.25-in. (6.4-cm) increments from 1 in. (2.5 cm) to 3.5 in. (8.9 cm)

- Mower deck returns to same preset height each time it is lowered

Storage tray under tractor seat

Storage tray under tractor seat

Exact Adjust tool used to level mower deck

Exact Adjust tool used to level mower deck

Storage for the onboard deck-leveling gauge and the Exact Adjust tool is provided in the storage tray under the tractor’s seat.

- Exact Adjust ports allow for easy and accurate leveling of the mower deck for optimum mowing performance.

Deck-leveling gauge placed under deck

Deck-leveling gauge placed under deck

Foot-pedal lift system

Foot-pedal lift system

Foot-pedal lift system

Pushing with the foot to raise the mower or implement is less strenuous for many operators:

- The easy-to-use raised position lock operates similarly to the park brake lock.

- The foot pedal is out of the way and not likely to catch on bushes and tree limbs when mowing.

- The mower deck returns to same preset height each time it is lowered.

- A spring is provided to minimize lift effort.

- An optional BM24810 supplemental lift-assist spring kit (X350R) is required for snow blower use on the X350R.

- The mower will not be inadvertently locked in the raised position when mowing through ditches.

- When installing or removing a mower or front equipment raised by the foot lift system, spring tension may be removed from the connection points by pulling rearward on the lift pedal and raising the lift latch to hold the pedal in the rearward position.

Parking brake control

Parking brake

Parking brake

Depressing brake pedal applies internal wet disk brakes (increased durability and longer life) for safe stopping.

Parking brake control is conveniently located for easy access; holds brake pedal securely in locked position.

Electric PTO clutch is easy and convenient to use

Electric PTO switch

Electric PTO switch

The heavy-duty electric PTO clutch is operated with a convenient dash-mounted switch.

Heavy-duty PTO clutch

PTO clutch

PTO clutch

The PTO clutch is designed to operate through many on/off cycles.

RIO and interlock switches

Reverse implement switch

Reverse implement switch

Using RIO

CAUTION: Children or bystanders may be injured by rotating blades. Before traveling forward or rearward:

- Carefully check the area around the machine.

- Disengage the mower before backing up.

NOTE: Operating the mower while backing up is strongly discouraged. RIO should be used only when operating another attachment or when the operator deems it necessary to reposition the machine with the mower engaged.

- Stop forward travel. Allow attachment to run.

- Look down and behind the machine to be sure that there are no bystanders.

- Push and hold in the reverse implement switch while depressing the reverse pedal slightly.

NOTE: If the attachment stops while positioning the machine, return the mower engagement (PTO) switch to off position. Repeat this procedure from the beginning.

- Release the reverse implement switch and reposition the machine as the machine begins to move rearward.

- Resume forward travel. The attachment should continue operating.

- Repeat procedure to position the machine again.

Interlock switches

Switch senses if hopper is installed

Switch senses if hopper is installed

A switch senses if the hopper is installed. If the hopper is not installed and the PTO switch is actuated, the PTO will not operate.

A brake interlock switch is provided so the tractor does not start unless the brake is depressed or the parking brake set.

A tractor seat switch turns off the PTO if the operator leaves the tractor seat; it also shuts down the engine if the park brake is not set and the operator leaves the seat.

Either the operator needs to be in the seat or the hopper or deflector needs to be installed for the engine to run.