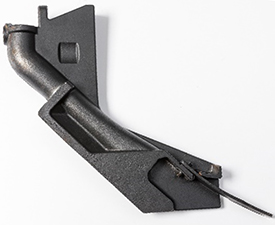

Narrow seed boot

Right-side view of seed boot

Right-side view of seed boot

Left-side view of seed boot

Left-side view of seed boot

On the ProSeries Opener, the seed boots are made of the same material as the older high-wear boots previously offered, which is a highly abrasion-resistant white iron. However, this seed boot is narrower, causing less soil throw on neighboring rows. It also sits up tight to the disk blade, resulting in less wear on the boot.

Seed boot

Seed boot

Below are two diagrams showing the seed boot comparison from the 90 Series Opener (highlighted in green) to the ProSeries Opener (highlighted in red). In these diagrams, the ProSeries seed boot is narrower and sits up tighter against the disk blade.

Seed boot comparisons

- ProSeries seed boot highlighted in red

- 90 Series seed boot highlighted in green

- A is the boot comparison at a 44.5-mm (1.75-in.) depth

- B is the boot comparison at a 63.5-mm (2.50-in.) depth

- C is the ground plane

Two inside views of seed boots (90 Series in yellow and ProSeries in green)

Two inside views of seed boots (90 Series in yellow and ProSeries in green)

The inlet/entrance diameter is 33 mm (1.3 in.) on the 90 Series and the ProSeries. The seed tube internal diameter is 27.4 mm (1.08 in.). The cross section is larger than the inlet for the 90 Series and ProSeries.

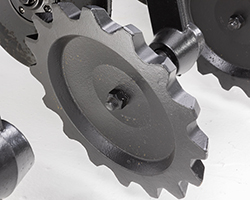

Serrated closing wheel

Serrated closing wheel

Serrated closing wheel

Serrated closing wheel:

- The serrated closing wheel offers an improved closing system when seeding into hard soils or high residue conditions. The notches help break up the top layer of soil covering the seed trench. The notches also reach through residue to seal off the trench better, rather than simply moving residue over the trench. Consistent soil over the seed bed provides optimal germination and emergence. The serrated closing wheel has performed well in all conditions but truly shines in high residue or hard soil conditions.

Smooth closing wheel:

- The smooth closing wheel is still offered for producers who seed into loose soil conditions with little residue. The smooth closing wheel has performed well over the years and has a long-lasting service life, keeping replacement costs down.

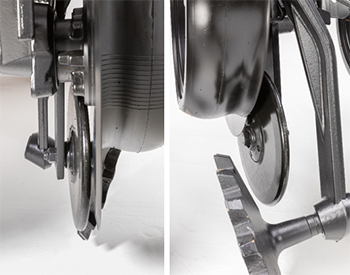

Narrow and flexible press wheel

90 Series press wheel

90 Series press wheel

ProSeries press wheel

ProSeries press wheel

The narrow and flexible press wheel has improved overall seed-to-soil contact. The improvement is in the shape and diameter of the press wheel. The ProSeries Opener press wheel profiles the trench better, partly due to the narrower and more flexible wheel itself, measuring 1.8 cm x 25.4 cm (0.71 in. x 10 in.). The 90 Series press wheel is 1.9 cm x 22.9 cm (0.75 in. x 9 in.).

Front view (left) and side view (right) of press wheel

Front view (left) and side view (right) of press wheel

Growers that have consistent seed depth have a greater opportunity for uniform emergence, uniform tillering, uniform flowering, and uniform maturity. This leads to increased yield potential, easier management of crop, and typically lower harvest loss on canola.

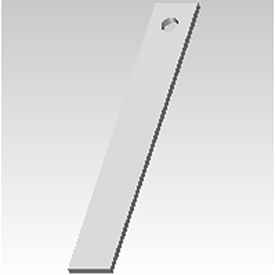

Improved seed tab

ProSeries Opener seed tab

ProSeries Opener seed tab

90 Series Opener seed tab

90 Series Opener seed tab

The ProSeries Opener has an upgraded seed tab that compliments the furrow much better. This seed tab, with an angled edge that profiles the trench better, also allows for consistent seed placement due to the flexible material that was designed to make it less brittle. This also minimizes seed bouncing, which increases overall seeding accuracy.

Spoked gauge wheels

Spoked gauge wheel

Spoked gauge wheel

Spoked gauge wheel

Spoked gauge wheel

Growers have historically had to make some difficult planting and seeding decisions due to weather. Operators have been forced to plant in wet conditions that are far from optimal in order to plant within the optimum planting window. Those operators have experienced poor performance from wet soils working in between the depth gauge wheel and the opener disk and not having a way out. This creates the possibility of the depth gauge wheel or opener disk to seize up and drag through the soil.

The spoked gauge wheel is a solution for operators who plant in these conditions to allow the mud and debris that get caught behind the depth gauge wheel to easily flow through the wheel and continue providing superior depth performance.

The spoked gauge wheel is designed for optimum performance. Its features include serviceable, stamped inner and outer rims. The wheel also has cast spokes and bearing hubs for increased strength. This allows for smaller spokes, creating larger open surface area for mud and debris to flow more easily than competitor’s wheels. Another improvement over the closed gauge wheel is a snap-ring bearing retention. Simply remove the snap ring, replace the bearing, and place the snap ring back.

Narrow gauge wheels leave more stubble standing

Optional 76.2-mm (3-in.) narrow gauge wheels

Optional 76.2-mm (3-in.) narrow gauge wheels

The 76.2-mm x 406.4-mm (3-in. x 16-in.) depth gauging wheel:

- Compatible with all 90 Series and ProSeries Openers

- Provides more clearance between openers for residue flow

- Leaves more stubble standing and disturbs less residue than the 114.3-mm x 406.4-mm (4.5-in. x 16-in.) gauge wheel

Gauge wheel snap ring

Gauge wheel snap ring

Replacing the bearing on the gauge wheel

Replacing the bearing on the gauge wheel

Heavy trash fields from no-till environments have also tested very well with the spoked gauge wheel. Some growers provided feedback of crop residue getting inside and jamming up the gauge wheel and opener. This spoked gauge wheel has shown exceptional performance within these areas as well. These wheels are compatible with both 90 Series openers on seeding tools and planter row-units.

Below is a chart that demonstrates a competitive advantage over MudSmith™ wheels for mud and residue flow:

| |

MudSmith |

John Deere |

Percent improvement |

| Open area |

329 cm2 (51 cu in.) |

471 cm2 (73 cu in.) |

43 percent |

| Rim height |

1.9 cm (3/4 in.) |

1.4 cm (9/16 in.) |

25 percent |

| Spoke width |

3.5 cm (1-3/8 in.) |

1.9 cm (3/4 in.) |

45 percent |

The wheel is serviceable along with other parts.

- AA86055 – complete wheel assembly

- A101570 – inner wheel rim half

- A101571 – outer wheel rim half

Not compatible in dual gauge wheel applications.

MudSmith is a trademark of MudSmith, LLC.