The 5E Series Tractor lineup offers the reliable nine-forward/three-reverse (9F/3R) top-shaft synchronised transmission. The concept of the proven 5E Series transmission provides:

- A wide choice of transmission speeds

- Easy and comfortable shifting

- A reliable, field-proven design made by John Deere

- High efficiency and reduced power losses

- A value-spec transmission

- A competitive price

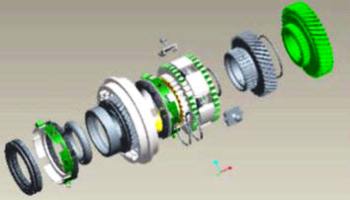

Top-shaft synchroniser

Top-shaft synchroniser

Top-shaft synchroniser

All 5E Series Tractors are fitted with the latest generation of soft-shift transmissions that can be shifted easily even by inexperienced tractor drivers.

What makes this soft-shifting possible is the top-shaft synchroniser. It equalises the speeds of mating gears to allow a clash-free shift while the tractor is in motion.

Inline shifting

Inline shifting

Inline shifting

Gear lever positioned close to the SCV joystick

Gear lever positioned close to the SCV joystick

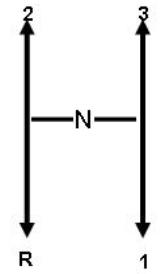

Quick-reverse manoeuvres during loader work or at the headland can be performed easily with unique inline shifting.

For inline shifting, second gear is positioned directly on the opposite side of the gear lever, so that the operator can change from the second forward gear into the reverse gear in one line. The second forward gear and the reverse gear have the same speed, which means that inline shifting can be used like a reverser. Due to the top-shaft synchroniser, this integrated reverser solution can be shifted softly.

The gear lever is positioned close to the selective control valve (SCV) joystick in order to change quickly between them when operating the implement or front loader during reversing:

Side-shift levers

Side-shift levers

Side-shift levers

Comfortable shifting without leaning forward—that is only one of the advantages of the side-shift levers. The range lever is conveniently located on the left hand of the operator. The gear lever is placed on the right-hand side to intuitively find the appropriate gear and range. All gear levers are colour coded in orange for quick familiarisation for inexperienced drivers.

Gear shifting

Gear shifting

Gear shifting

The gear-shifting lever is ergonomically placed within a hand's reach, which is ideal for the operator. The forward gears and one reverse gear can be shifted in short, crisp lever movements. When in neutral, the gear lever automatically goes into the slot between the second and third gear, which makes shifting very convenient, especially when travelling on a road when gears need to be shifted quickly.

All gears are synchronised.

Range shifting

Range shifting

Range shifting

Three ranges are provided to always find the perfect gear for each single application. High-contact helical gears provide large-tooth contact for great torque transmission capability and quiet operation.

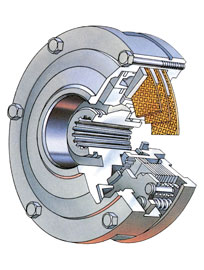

PermaClutch 3 reduces service and maintenance costs

PermaClutch 3

PermaClutch 3

PermaClutch is back. Hydraulic, wet, forward, and reverse clutches are permanently lubricated by cooled oil to maximise durability for the long life of a tractor.

The operator does not have to service the PermaClutch 3 on the tractor after 5000 to 6000 hours, which is the average service interval for a dry clutch disc change.

This results in less service and maintenance costs.

Dual clutch

Dual clutch

Dual clutch

Reliable and field-proven dual clutches are used in 5E Tractors, one for the power take-off (PTO) and one for driving. The dual clutch ensures independent operation of the PTO, which ensures that the PTO can keep running when the driving clutch is disengaged. This ensures enhanced productivity.

All 5E Series Tractors feature a dry design clutch with a diameter of 280 mm.

Standard and economy PTO

Standard and economy PTO

Standard and economy PTO

All 5E Tractors have the 540 Standard and 540 Economy PTO as standard. The 540 Economy PTO can be driven at only 1705 engine rpm. This allows lower fuel consumption and lower noise emissions, and is more cost efficient. The 540 standard PTO is driven at 2400 engine rpm.

Quick-headland power take-off (PTO) control

Electro-PTO engagement and disengagement on headlands

Electro-PTO engagement and disengagement on headlands

Together with the electro-reverser, there is also a electro-PTO engagement available. This means when the operator reaches end of field with tiller, the operator just needs to fingertip a soft-push button, which is located close to the raise-lower lever, so the operator can manoeuvre controls quickly for tournament.