Cam track design offers the best versatility

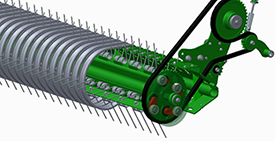

Left – pickup with cam track / right – cam-less pickup

Left – pickup with cam track / right – cam-less pickup

The F441M Baler provides operators with a single baler to harvest all kinds of crops, from gliding straw to short, sticky silage. Cam-track technology provides an efficient solution for such needs. The traditional stripper design provides reduced space between the pickup tines and rotor feeder, while the tine motion helps to avoids pinching.

The cam-less technology requires long strippers, creating a dead-zone between the tines and rotor. Additionally, fixed tines can easily pinch crops in sticky conditions, causing plugs that need to be manually removed.

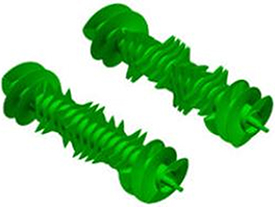

Four tine bars match good picking capacity

Four tine bars match good picking capacity

The F441M Balers feature a 2.0- or 2.2-m (6.5- or 7.2-ft) pickup and galvanized strippers for an extended lifespan. The four-tine bars mounted on sealed ball bearings and equipped with 5-mm (0.2-in.) diameter tines meet the picking capacity expected by small and medium size farms.

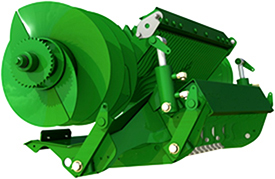

High-capacity (HC) rotor limits plugging risk

Left - HC rotor / right - classic rotor design

Left - HC rotor / right - classic rotor design

The F441M features an HC rotor design already used on the previous model F440M. This simple design offers several key advantages:

- Large-diameter rotor to provide high feeding capacity

- Limited distance from pickup to rotor tines to reduce plugging

- Reduced number of bearings and distributed loads along the rotor to increase reliability

- Hardox® wear plate tines to provide high resistance to wear

RotoFlow HC and MaxiCut™ HC 13 rotors are available on the F441M

RotoFlow HC and MaxiCut™ HC 13 rotors are available on the F441M

The F441M is available without a precutter (RotoFlow HC Premium feeder). MaxiCut HC Premium 13 knives is proposed as alternative solution for operators searching for a regular precutter with 80-mm (3-in.) space between knives. In order to provide quality cutting, knives are individually secured by springs to protect against foreign objects and are double heat treated for longer durability. The full set of knives is controlled by a hydraulic valve conveniently located on the front of the baler.

Advanced drop floor or simple rotor wrench offer unplugging choice

Exclusive drop floor removes the worst plugs

Exclusive drop floor removes the worst plugs

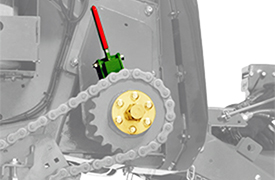

Rotor wrench offered as an economical solution for RotoFlow HC Premium

Rotor wrench offered as an economical solution for RotoFlow HC Premium

As with the high-spec F441R Baler, the drop floor makes removing plugs easy, even those under converging augers. This exclusive design covers the rotor width, so wherever a plug occurs, the unplugging device decompresses the crops and feeds the plug into the baler.

Parallel kinematics provides a consistent 40-mm (1.6-in.) space on the entire drop floor, eliminating narrow pinch points like front- hinged drop floors have.

The drop floor is easily controlled by a hydraulic valve located on the control panel. The drop floor is standard for the F441M, when equipped with the MaxiCut HC Premium 13.

For a RotoFlow HC Premium equipped baler, the drop floor system is proposed as an option. Even without this system, the F441M can be unplugged without the operator reaching their hands into the pickup. If this happens, the operator needs to declutch the rotor, put the wrench on the rotor, and reverse to remove the compressed crops.

Hardox is a trademark of SSAB Technology AB.