Proven high density and bale weight

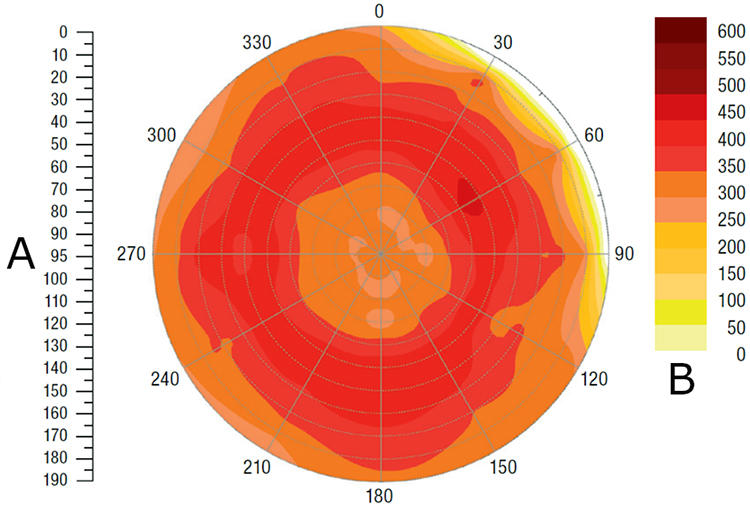

A is bale diameter (cm) symmetric across the 0-degree axis, and B is bale density (kg/m3)

A is bale diameter (cm) symmetric across the 0-degree axis, and B is bale density (kg/m3)

Deutsche Landwirtschafts-Gesellschaft e.V. (DLG) official silage bale test

| Test data |

| Date |

23 June 2012 |

| Harvested crop |

Grass silage |

| Baler |

John Deere 960 |

| Bale number |

12 |

| Bale weight |

786 kg (1732.8 lb) |

| Bale density |

505.8 kg/m3 (31.6 lb-ft) |

| Bale diameter |

127 cm (50 in.) |

| Bale width |

123 cm (48.4 in.) |

| Dry matter content |

68.8 percent |

| Density setting |

100 percent |

| Number of knives |

13 |

| Driving speed |

14.3 km/h (8.9 mph) |

A is bale diameter (cm) symmetric across the 0-degree axis, and B is bale density (kg/m3)

A is bale diameter (cm) symmetric across the 0-degree axis, and B is bale density (kg/m3)

DLG official straw bale test

| Test data |

| Date |

13 August 2012 |

| Harvested crop |

Wheat straw |

| Baler |

John Deere 990 |

| Bale number |

3 |

| Bale weight |

472 kg (1040.6 lb) |

| Bale density |

125.3 kg/m3 (7.8 lb-ft) |

| Bale diameter |

192 cm (75.6 in.) |

| Bale width |

126 cm (49.6 in.) |

| Dry matter content |

88.5 percent |

| Density setting |

100 percent |

| Number of knives |

--- |

| Driving speed |

17.7 km/h (11 mph) |

The C451R can produce bales up to 1.60-m (5.2-ft) diameter with a 1.21-m (4-ft) bale chamber width. The MaxD – Maximum Density – bale chamber has been designed to deliver very heavy, dense, and perfectly shaped bales, officially proven by DLG.

Offset density arm provides tension to the belts

Offset density arm gives tension to the belts

Offset density arm gives tension to the belts

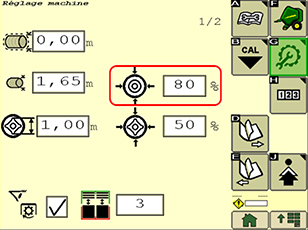

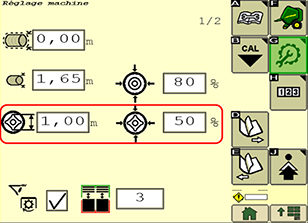

Simple density settings from monitor

Simple density settings from monitor

The C451R density is provided by an offset tension arm that applies hydraulic tension to the belts and not directly to the bale. This heavy-duty component is not involved in belt length compensation, so 100 percent of hydraulic power is involved in belt tensioning.

Density is easily set from the monitor and can be adjusted from 0 to 100 percent of hydraulic pressure. A virtual gauge located on the main working page continuously follows the density increase without looking back to the baler.

Density can also be adjusted manually from the hydraulic valve in case of major failure.

Standard softcore system provides perfect crop quality

Softcore is fully adjustable from monitor

Softcore is fully adjustable from monitor

The C451R and C461R both benefit from a standard advanced softcore system management:

- Bale core density (different from the overall bale density) can be adjusted from 0 to 100 percent of maximum density capacity from the monitor.

- Bale core diameter can be set from the monitor.

- Softcore system can be activated/deactivated from the display.

Accurate softcore settings allow:

- Production of better-quality forage when harvesting crops with residual moisture.

- To easily unroll core of bales.

Hardox is a trademark of SSAB Technology AB.

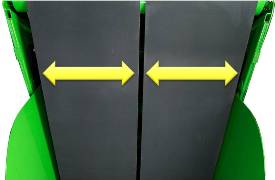

Wide endless belts provide density and reduce crop loss

Only two belts - advanced belt tracking allows the operator to work in all conditions

Only two belts - advanced belt tracking allows the operator to work in all conditions

The C451R Round Balers feature two wide 573-mm (22.56-in.) belts, meaning that only three free spaces are observed (one between the two belts plus one on each belt side). Compared to a traditional 5/6 belts solution, only using two belts optimizes bale coverage by approximately 4 percent. The result is significant crop loss limitation and more efficient baling process.

To be able to handle huge stress transmitted by the density arm, the belts have no lacers.

An advanced belt tracking system, including wide front pulleys and several guides located throughout the chamber, ensures accurate belt positioning, even when working in slopes or when overloading one pickup side. All edges of parts potentially in contact with the belts are chamfered to avoid belt side damage. A take-up arm manages belt tension compensation during the unloading process to avoid potential belt tracking issues.

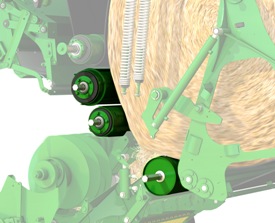

Belts are driven by two large-diameter rubber rolls with a large contact surface that avoid belt slippage in very wet conditions. Springs linked to the density arm are located on both sides of the chamber and give enough tension to the belts from bale starting.

To limit crops from sticking, belts feature a smooth pattern. Paddles on belts' driving rolls, cleaning augers into the density arm, and other scrapers located in several places through the belts paths continuously clean the belts and remove crop accumulation around the bale chamber.

Bale chamber rolls make easy bale starting in all conditions

Driven bale chamber rolls rotate crops immediately

Driven bale chamber rolls rotate crops immediately

MaxD bale chamber features three powered rolls to improve versatility and bale quality:

- The three powered rolls facilitate bale starting, especially in wet conditions such as silage. Forage immediately turns into the chamber, and there is no slipping risk even with the heaviest bales.

- Rolls are positioned to give the bale a perfectly round shape, regardless of the bale diameter, and the core is ideally centered.

- As belts push crops against rigid steel rolls, high pressure is easily applied and provides high-density bales.

Heavy-duty components team high density and durability

Reinforced bale chamber components (in red)

Reinforced bale chamber components (in red)

Heavy bales, high density, high baling speed, and high tractor power directly impacts baler durability. The C451R Round Baler includes several heavy-duty components into the bale chamber to meet growers’ expectations:

- The front part of the bale chamber (front side sheets) – the most stressed area – is made with Hardox® steel plates to limit impact of aggressive crop friction.

- Lower Fast Release System (FRS) roll handling a large part of the bale weight features extra thickness (plus 40 percent versus standard rolls) for extended durability.

- Tailgate frame is specially reinforced around the lock to handle huge tension.

- Top belts driving roll receive a special heat tempering.