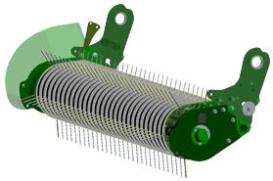

New pickup design improves capacity and durability

Large-diameter stripper and five teeth bars improve picking capacity

Large-diameter stripper and five teeth bars improve picking capacity

The C440R Baler uses the same, highly-productive and efficient pickup of the 900 Series Variable Chamber Balers. To fit all conditions, the baler is available with 2.0-m (1.86-m DIN) or 2.20-m (2.12-m DIN) width.

The pickup features five tines (four on the F440M) bars with a low-rotating speed. The large-diameter strippers allow five tines bars in the pickup instead of four on the previous series. The picking capacity is increased by more than 10 percent. While picking capacity is increased, the rotating speed decreases by 12 percent. With bearings added to the cam track, all of these features provide a smooth and quiet ride with extended uptime.

In addition to the high spec features, the C440R benefits from stainless steel strippers, a market exclusivity. Stainless steel provides the following advantages:

- No rust

- Constant gliding capacity

- High-resistance to aggressive additives such as propionic acids

The C440R Balers pickup uses the cam track design. The cam track design provides a better quality solution when harvesting wet crops. Contrary to the cam-less design, the cam track pickup:

- Features a short space between the tines and rotor, limiting dead zone.

- Avoids pinching area, so no crops are plugged into the pickup drums.

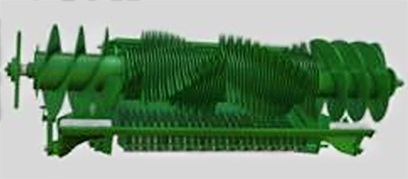

High-capacity (HC) rotor for higher productivity

Maxicut™ HC 25 has a single axis for rotor and converging augers

Maxicut™ HC 25 has a single axis for rotor and converging augers

Maxicut™ HC 25 has a single axis for rotor and converging augers

Maxicut™ HC 25 has a single axis for rotor and converging augers

In order to maximize productivity in the toughest swaths, the C440R Baler features a HC rotor design. Converging augers are aligned with the rotor, limiting the free space between pickup teeth and rotor. Plugging risk is also decreased and crop transfer is highly improved. The simple HC rotor design also reduces the number of moving parts and provides reliability. For example, stress on the rotor is distributed along all of the rotor and overhang load on the bearings is avoided.

The C440R is only available with a precutter, offering space between knives as short as 40 mm or 80 mm.

|

Maxicut HC 13 |

Maxicut HC 25 |

Number of knives |

0/13 |

0/12/13/25 |

Space between knives |

Full crop length 80 mm

|

Full crop length

40 mm 80 mm |

Best use |

Silage, hay, straw |

Silage, hay, straw |

High cutting quality provides better forage

Double-heat treatment for concise cut and long life

Double-heat treatment for concise cut and long life

Individual knife security for quality forage

Individual knife security for quality forage

The C440R Balers are efficient in baling a high amount of cut silage. The Maxicut HC 13 and Maxicut HC 25 feature exclusive high-quality knives, providing several advantages:

-Bulk heat treatment to reduce risk of knife breakage.

-Surface heat treatment of the cutting area to provide better cutting quality and knife durability.

Select number of knives from the cab to increase uptime

Knive sets from the cab with Maxicut HC 25

Knive sets from the cab with Maxicut HC 25

The C440R can be used on several kinds of crops, in which knives can be engaged or removed. No matter the rotor type or monitor, this operation is easily managed from the cab.

When using the Maxicut HC 25 precutter, crops can be cut as short as 40 mm, but only half of the knives can be engaged. This system proposes to use two different sets of knives for the same cutting width, to allow the use of sharp knives longer. By using sharpened knives versus blunt, fuel consumption can be decreased by up to 10 percent.

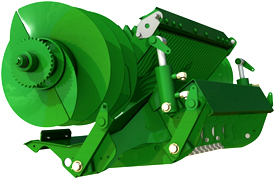

Drop floor can remove the worst plugs

Drop floor covers rotor full width

Drop floor covers rotor full width

Parallel kinematics avoids narrowing

Parallel kinematics avoids narrowing

No matter the operator experience, plugs can still occur, especially with large silage swaths. The C440R is equipped as a base with a drop floor unplugging system. Same as the 900 Series Balers, the F440R drop floor features exclusive advantages:

- Full width design - by covering the full pickup width, the device is able to remove plugs, even located under converging augers.

- Parallel kinematic - no rear or front hinge means no narrowing. The C440R drop floor offers a constant 40-mm free space through the feeding channel when activated. This is enough to decompress the crops and avoid crop loss.

No matter the precutter or monitor type, the drop floor unplugging system can be easily managed from the cab.