StalkMaster row-unit

StalkMaster row-unit

The StalkMaster corn head chopping system allows operators to size and chop corn stalks while harvesting, eliminating second-pass operations and saving time. StalkMaster is available on 706C, 708C, 708FC, 712C, 712FC, 716C, and the 718C Corn Heads.

Feature benefit:

Uniform sizing of corn stalks to speed decomposition and provide for soil protection from wind and water.

Eliminates the need for the second-pass operation to size stalk residue, saving time and expense.

Agronomic needs of individuals matched easily because the StalkMaster can be equipped with either intermeshing or opposed knife stalk rolls.

Ultimate flexibility to chop or not chop when desired through a quick,no tools required disconnect feature

Functionality

StalkMaster chopping blades

StalkMaster chopping blades

Each StalkMaster row-unit gearcase is equipped with two heat-treated and wear-coated rotating blades positioned below the stalk rolls. As stalks are pulled through the rolls stalks are cut to size and distributed evenly throughout the row. If the blades encounter an obstruction they will swing backward avoiding damage and interruption to harvest. Blades can be reversed to extend their useable wear life.

StalkMaster chopping disconnect feature

StalkMaster chopping disconnect feature

The gearcase on the StalkMaster row-units feature a no tools needed disconnect. Each row has a convenient shifting lever on the right side of the gearcase to turn the function on or off in a matter of minutes.

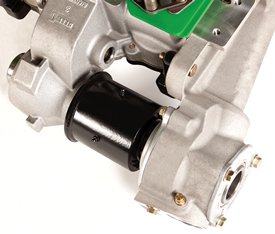

StalkMaster gearcase

StalkMaster gearcase

A heavy-duty slip-clutch design protects both the row-unit gearcase and the StalkMaster lower chopping unit gearcase. If the clutch slips, the operator will know immediately.

712C right-hand side and drive shaft

712C right-hand side and drive shaft

Enclosed chain cases drive the gathering chains and stalk rolls for each row to provide robust durability and uninterrupted harvesting. Heavy-duty bearings mounted in machined castings along with O-ring seals increase life and improve serviceability.

Rubberized curtains

Rubberized curtains

Steel-protective shield

Steel-protective shield

StalkMaster chopping heads feature side- and rear-mounted rubberized curtains to optimize chopped crop residue distribution. Also, the right-hand side of the head has an additional shield for protection from protruding blades.

Larger sprockets and chain

Larger sprockets and chain

Continuous-loop American National Standards Institute (ANSI) #100 chain allows for higher loads and longer life by eliminating all connector links and half links. The large-diameter sprockets along with large 38-mm (1.50-in.) transverse hex back shaft and row-unit shafts provide improved sprocket and chain life.

Telescoping drive shaft

Telescoping drive shaft

Telescoping drive shafts mount to the splined feederhouse back shafts on all 50, 60, 70, W-, T-, C-, and S-Series Combines.

The coupler features an 8-degree index, allowing the operator to match the drive shaft splines without rotating the platform feederhouse.

Telescoping drive shafts:

- Feature fast, no-tools coupler

- Can be retrofitted to earlier 90 Series and 40 Series Corn Heads