Power

John Deere R-Series Loaders are available with different types of leveling systems

John Deere R-Series Loaders are available with different types of leveling systems

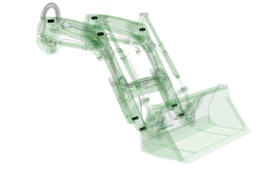

Due to the design and the loader kinematic, the R-Series Loaders feature outstanding power in regards to lift capacity and lift height. The power of the John Deere tractor is transferred to the loader via the hydraulic system.

The underslung leveling link of the mechanical self-leveling (MSL) loader is connected to the false rod cylinders which results in fast cycle times (dumping and rolling back). The geometry allows more rollback capacity which gives the operator stronger breakout forces to work with. The compact boom has lower pivoting points for easy access to grease points.

The detailed specification of the loaders give an overview of the lift height and lift capacity of each loader (543R, 603R, 623R, 643R, 663R, and 683R).

Durability

John Deere R-Series Loaders are built with a high level of durability

John Deere R-Series Loaders are built with a high level of durability

Durability supported by torque tube

Durability supported by torque tube

The R-Series Loaders show a great level of durability due to the high-quality material. The modular cast-iron components on the loader are the foundation of a durable machine. The cast-iron mounting frames ensure a strong base for heavy-duty applications and guarantee a good connection to the tractor frame. This results in tested, reliable longevity.

The position and shape of the torque tube supports the heaviest loader applications and guarantees a stable behavior of the tractor and loader combination. Additionally, the compact boom design and the loader kinematics result in a strong and reliable solution the customer can experience in the field.

Front loader on the test bench

Front loader on the test bench

Cast-steel parts on the loader

Cast-steel parts on the loader

To ensure a high quality with outstanding durability, the R-Series Loaders have been tested on a dedicated front loader test bench, where the loader is subjected to heavy duty farming operations. All pivot points are designed with a wider contact surface and are made from cast-steel material. The pivot pins has a dedicated diameter and undergo a specific treatment to ensure an outstanding durability.

The welded, directional bushings have a specific shape to provide ideal stress distribution and support the heavy-duty applications.

Major pivot points are equipped with replaceable bushings for low frequency of greasing, because the grease continuously is delivered during the loader work. New bushings can be installed thanks to the specific bushing design.

Position of pivot points on the loader

Position of pivot points on the loader

Hydraulic integration

Hydraulic lines are laid inside the boom

Hydraulic lines are laid inside the boom

With the John Deere loaders, the oil lines have been routed through the boom arm to protect them from any damage and to additionally increase the visibility of the driver. To provide good access to the hydraulics hoses, they are located on the top of the torque tube. The torque tube cover protecting the hydraulic components can be dismounted easily.

The loader suspension is located in the torque tube to protect the gas accumulator against external influences.

Safety feature

Shut-off valve open

Shut-off valve open

Shut-off valve closed

Shut-off valve closed

A hydraulic shut-off valve is included in base with the R-Series Ag Loaders to ensure the loader does not lower suddenly. This allows the boom to be locked if someone is required to be located under the loader boom, for example, during service work on the tractor.

False rod cylinder

False rod cylinder

False rod cylinder

Fast bucket cycle times are important to dump the load from the bucket to be as productive as possible, while completing loading operations. The bucket cylinder design can have a major impact on the cycle time, especially for the mechanical self-leveling (MSL) loaders.

All MSL R-Series Loaders utilize false rod bucket cylinders. A false rod cylinder has a smaller displacement of oil requirement on the head end of the cylinder, which allows the cylinder to retract much faster than a normal cylinder.