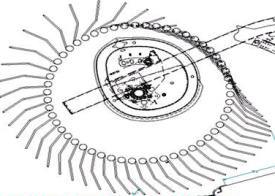

435D split-span reel with plastic fingers

435D split-span reel with plastic fingers

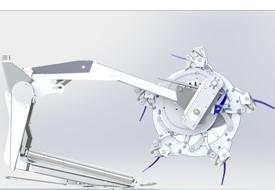

Cam reel tooth action

Cam reel tooth action

Reel in full forward position

Reel in full forward position

The 400D Draper Platform features a cam design reel that feeds well in all crop conditions.

The cam pickup reel features a 165-cm (65-in.) effective diameter and utilizes heavy-duty plastic or steel fingers and heavy tine tubes. The reel features a cam to control tooth position. The smooth cam action and heavy tine-tube design allows the reel to operate at higher speeds with a smoother, quieter operation. This gives better feeding with less wear on the reel drive components and, more importantly, less shatter of the crop harvested.

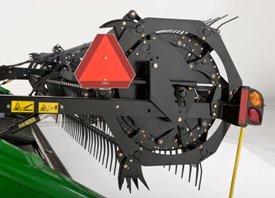

Hourglass-shaped reel

Hourglass-shaped reel

Reel endfingers

Reel endfingers

The reel is designed and assembled to have an hourglass shape. This allows the ends to be positioned closer to the cutterbar for positive feeding while keeping the fingers at the center of the reel span from coming into contact with the cutterbar. Feeding is most important at the ends. Other reel designs do not have the capability of such tight adjustment. The hourglass shape is designed with an adjustable bolt position on the reel tine tube brackets to the disks.

Optional end fingers improve feeding aggressiveness in difficult feeding and cutting conditions with down and tangled crop.

Adjustable cam positions

Adjustable cam positions

The cam position and reel position are adjustable, enabling the machine settings to be matched with the crop conditions for a trouble-free harvest. The finger release position is easily adjustable to one of four cam positions.

The reel is hydraulically positioned up, down, and fore-aft to allow perfect positioning for gentle yet positive feeding action.

Plastic fingers come standard from the factory on all platforms. Steel finger options are available through Parts and are recommended for heavy forage crop conditions due to their longer life. The plastic fingers are recommended for all crop conditions. The plastic fingers weigh less and work well in all crops. The plastic fingers are easier to replace individually without having to disassemble the other fingers on the reel tube section.

All 10.7-m (35-ft) split-reel platforms (North America and export) and the 12.2-m (40-ft) split-reel platforms (North America only) come standard with tine tube stiffener kits to handle heavy crop conditions and improve the life of the platform.

Plastic tine split reel with end feed fingers

Plastic tine split reel with end feed fingers

The reel is available in a single span only from 4.6-m (15-ft), 6.1-m (20-ft), and 7.6-m (25-ft) sizes. Single-span or split-reel spans are available in 9.1-m (30-ft) to 10.7-m (35-ft) sizes. Split reel only is available in 12.2 m (40 ft) size. There are optional end feed fingers (three per end are available as field installed) for tough feeding conditions.

The single-span reel offers less weight and better center visibility. It is a good option for producers who harvest canola and small grains for oil and seed.

The split-reel span gives better feeding in adverse crop conditions such as heavy, wet, and down crop. The split span gives better control of the reel height on wider platforms for more consistent feeding.

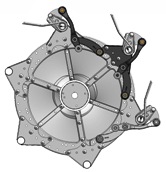

Five-bat reel

Five-bat reel

Six-bat reel

Six-bat reel

Nine-bat reel

Nine-bat reel

The reel is available in five-, six-, or nine-bat configurations. The nine-bat configuration provides more interaction for more positive and smooth crop flow in heavy down crop conditions. Additional bats can be field installed to convert from six bats to nine bats. Additional bat configurations are recommended for heavy crop conditions such as silage and grass seed crops.