ProStream™ crop flow

ProStream crop flow

ProStream crop flow

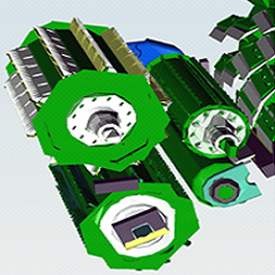

A key concept for the 8000 Series Self-Propelled Forage Harvester (SPFH) line was to position all crop-flow components to avoid any flow obstacles, as well as to design the crop path for minimum kinetic friction on the particles.

The 8000 Series crop-flow channel begins at the harvesting unit pickup tines or crop-row pointer. On the actual harvester, it starts with the feedroll arrangement. John Deere has implemented a concept layout well proven on the 7000 Series.

Key characteristics are a set of front feedrolls where, when the header interface is in a vertical position, the upper-front feedroll (UFFR) reaches out about 60 mm (2.4 in) over the crop in front of the lower one, grabbing the mat from the harvesting header and pulling it into the feedroll gap. This is a key function when corn headers without feed augers are mounted, assuring the machine’s crop feeder is the sole length-of-cut (LOC) metering unit of the harvester.

On its way to the cutterhead, the radial-arc-feed roll arrangement applies pressure to the crop for superior cut quality. The crop mat is perfectly compressed until the last second before transitioning into the knives.

From the moment the knife pockets start unloading, the cutterhead band takes the crop particle stream, collecting it for launching into the crop chute.

The crop path follows a constant curve between the cutterhead floor and the accelerator entrance. The crop accelerator, the spout transition, and the spout build the machine’s crop discharge device. All components that have an acceleration impact on the crop perfectly integrate tangentially into this curve for a fully unobstructed crop flow.

With 1800 rpm, the accelerator provides sufficient thrust to the crop stream for secure overloading with the largest of heads without consuming excessive power. Rather than being carried by the accelerator rotor, the crop follows the curve of the accelerator band before transiting via the transition cone directly into the spout base, from where on it follows the spout contour.

The crop hits the transition front liner just below the spout entrance at a shallow angle, minimizing component wear and inertia losses. This constant flow curve was designed to the spout as gently as possible so that the crop flow components had the least friction effect on the crop particles.

Sufficient space on the vehicle for a cab that allows for more operator leg room, though keeping the overall machine compact, was a key demand.

Ultimately, the 8000 Series SPFHs provide superior crop-flow efficiency, resulting in industry-leading machine capacity in respective horsepower classes as well as low specific-fuel consumption (liter of diesel per ton of crop harvested). Combined with Dura Line™ technology, the 8000 Series SPFH triggers the lowest possible machine maintenance with minimal cost of operation.

8000 Series crop discharge

Crop accelerator

On its way to the trailer, the crop has to be elevated more than 4 m (13 ft) high between the accelerator exit and the spout end. It has to overcome a certain friction along the transition and spout liners until it is ejected off the spout end cap. When opening corn fields, producers can expect crop being airborne over a distance of 15 m to 20 m (50 ft to 65 ft) into the following trailer.

It is the task of the crop accelerator to provide sufficient thrust with appropriate efficiency to the crop particles to be securely loaded in all circumstances. An exactly specified air inlet in the accelerator housing assures a perfect spout crop jet when the kernel processor in place obstructs the natural air flow from the cutterhead to the crop accelerator.

Crop transition

The crop transition cone is completely lined with high-grade wear elements, which can easily be inspected and replaced from the machines service compartment through an access hutch. A unique manufacturing process allows even customized punctual hardening of the wear liners, perfectly addressing the individual wear situation in the cone. The transition is bearing the massive head gear-driven spout turning mechanism.

8000 Series SPFH features a spring-loaded cam-torque limiter inside the spout-turning drive mechanism. The spout hitting an obstacle is perfectly secured. However, the spout would never rotate uncontrolled and hit the cab. The spout turning sensor precisely monitors the spout position even when the spout safety device would have been triggered and mechanical end stops additionally secure the system.

High-arc spout with available extension

High-arc spout with available extension

There is a set of intermediate spout sections of various lengths addressing the crop overloading distance relative to SPFH header width. For weight reasons, the spout extensions are built from aluminum alloy with a thin steel liner inside. The spout end-cap module bolts to those intermediate sections.

The standard configuration shipped from the factory would be dedicated to grass harvesting with a windrow pickup or corn harvesting with a 6-m (20-ft) corn header. Other spout segments to extend the spout for 7.5-m (25-ft) or 9-m (30-ft) header widths are bi-packed with the harvester if ordered.

Hardox is a trademark of SAAB.

IVLOC™ system

Infinitely variable length of cut IVLOC

Infinitely variable length of cut IVLOC

The entire feeder assembly is driven from the main feedroll transmission on the right-hand side of the roller frame. Power is sourced from the hydrostatic motor. The static set of lower-front feedrollers is directly driven from the gearcase. The moving set of upper-front feedrollers have their proper transmission on the left-hand side supplied with power via a transversal U-joint shaft. The main concept driver is to allow wider crop channels inside a narrower machine fit with the biggest tires in the industry.

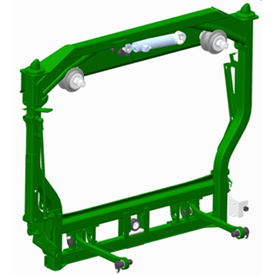

Header mounting and ground contour following

Header mount

Header mount

8000 Series front-end interface is a laterally tilting frame. Multiple factors led to John Deere’s common harvesting units interface plate and redesigned header mounting, including:

- The need for more front feedroll travel as well as a greater roll diameter addressing the increased harvesting capacity of the new line.

- The intention to integrate the lateral tilt device into the harvester vehicle, because the larger feedrolls of the machine would not allow for enough tilt with the combine interface.

- The ground adaptation can be passive, with a set of springs bringing back the frame into neutral level position or active (optional) with a hydraulic cylinder, positioning the header in reference to the signals from AHC sensors on the respective header.

This change eliminates multiple lateral-tilt devices on headers. An additional advantage is the header's self-centering feature of the attaching cones on the frame required to implement the automatic header drive-shaft coupler. Central header locking is a standard feature and comes with the hydraulic multi-coupler.

Spout with multiple length components

Spout with multiple length components

Spout

The spout on the 8000 Series features modular architecture. On the basic module, the wear liners are a structural part of the component. This module features a box design closed by the wear liner. A worn-through liner discovered too late would not lead to damage of the spout structure, but replacement would rebuild the spout like new.

The liner of the base module is segmented addressing the wear situation on individual sections. In the standard configuration, all four liners on the base module are made of Hardox® steel; however, for severe conditions, section one and two can be specified in Dura Line™ version.

When specified with HarvestLab™ sensor, section two would carry the near-infrared (NIR) sensor. In this case, the wear liner always comes in Dura Line™ version, and it would feature quick-attach clamps for easy maintenance of the HarvestLab sensor.

The HarvestLab installation is tremendously facilitated by directly bolting to the wear-liner segment. The NIR sensor is once aligned with the carrier sheet, and whenever serviced, the entire assembly is then unlatched from the spout and then re-clamped.

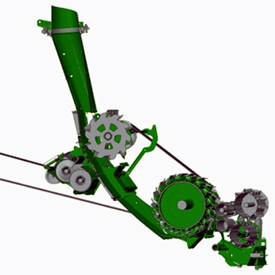

Crop intake

Crop intake rolls

Crop intake rolls

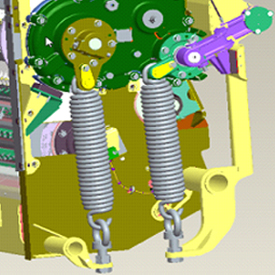

Mechanical spring

Mechanical spring

8000 Series Self-Propelled Forage Harvesters (SPFH) use four feed rolls to ingest crop with the top rolls pulled down by four springs. Their tensioning can set manually. All four rolls are driven with an infinitely variable transmission (IVT™) and speed synchronized to ensure smooth and reliable feeding of the cutterhead.

Feedrolls

The front set of feedrolls in charge of taking the crop off the front-end harvesting unit have been redesigned to be more adaptive to the tremendous variability of harvesting conditions.

The upper-front feedroll (UFFR) is now solely a ridge-type design and standard fit with replaceable and reversible wear slats. The ridges feature a triangle-teeth design and are part of the roll segments. Behind the ridges there are tapered composite teeth bars clamped on the segmented roll. The wear slats feature the same triangle-teeth design on one side and are smooth on the other side, which makes them ideal to adapt the roll to the full range of crop conditions from dry and smooth hay to wet and sticky alfalfa clover.

The lower-front feedroll (LFFR) features a similar design; however, replaceable teeth bars with identical serration are optional wear elements. Inside the lower front feedroll is a rectangular tube carrying the metal detector coils and housing the optional stone detection sensor, helping the operator to enjoy full machine and crop protection.

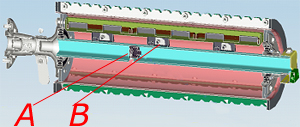

Machine foreign-object protection

Sensors

Sensors

A - Stone-detector sensor

B - Metal-detector sensor

The electro-magnetic metal detection system with its multi-sectional sensor coil is standard on all John Deere SPFHs. When tripping, metal object location in the crop mat is indicated in the cab.

Optionally, this safety device can be completed with an additional stone detection feature where a sensor is placed in the LFFR rectangular tube inside the roll. This sensor is correlated with a second one on the right-hand side UFFR arm, detecting knocks on the roll as well as jerk feed roll movement. Both sensors are redundant, and as a result the verification of a solid foreign object, is significantly improved, minimizing stone detector false tripping.

When tripping, both metal detector as well as stone detector would trigger selective control valve (SCV) 1 on the SPFH to automatically raise the crop compressor device on the grass pickup. Re-engaging the feedrolls would then lower the device into place again.

Header drive and control

The 8000 Series SPFHs supply crops to the chopping components.

Improvement is driven by automatic header detection, variable and efficient hydrostatic header and feeder drive concept, revised header ground contour following, sophisticated machine protection technology, and feedroll redesign.

Automatic header detection

8000 Series machines are equipped with the multicoupler interface for all hydraulic and electric services to the SPFH harvesting headers. Through the electric wiring coding in the multicoupler, distinct header identification is assured, allowing it to automatically refer to customized header settings stored in the respective controllers onboard the SPFH. This allows the operator to instantly call back all settings that resulted from the last harvesting experience. All calibrations required for proper header operation are automatically recalled in full when attaching the header.

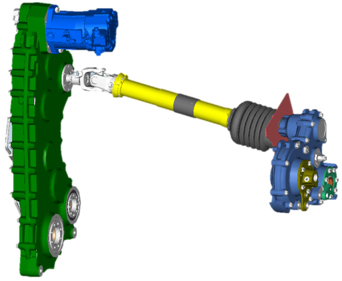

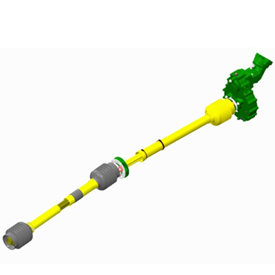

Hydrostatic header drive

Header drive line

Header drive line

Header drive coupler location

Header drive coupler location

On the 8000 Series, the harvesting headers are driven by a hydrostatic service. The hydrostatic pump on the machine’s main power take-off (PTO) transmission supplies power to the motor behind the vehicle front axle. A U-joint shaft assembly transmits the torque to the header entry transmission.

An optional dual-header drive provides a power split to the feeding components such as on a grass windrow pickup. In this case, the hydrostatic service would drive the pickup auger and a second hydraulic service would separately power the pickup tine reel.

Variable oil-flow control allows easy synchronization of drive speeds with the velocity of respective components on the harvester. The entire header can be driving with a constant speed setting, or the header main drive can turn at a desired speed ratio synchronized with the harvester’s feedroll speed.

The dual drive allows individual synchronization of the header feed auger with the feedrolls and the header tine reel with the vehicle’s forward speed when harvesting.