Large high-capacity auger

Large high-capacity auger

Large high-capacity auger

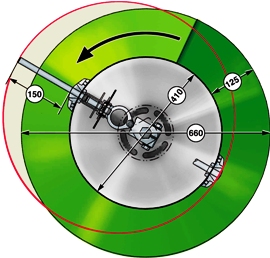

All 600R Series Cutting Platforms feature a large, 660-mm (30.7-in.) auger with deep auger flights to handle large amounts of crop. This design provides a very big area under the auger to aggressively feed large volumes of crop material. The high-capacity auger is available in two different versions, the standard auger and the wear-resistant auger.

Feature benefit:

- All augers are equipped with retractable auger fingers over the full width of the auger

- Auger fingers are designed for quick replacement and mounted with a finger retainer

- Auger finger retainers prevent broken fingers from being moved into the combine, minimizing the potential damage caused by rocks and other obstructions

Full finger auger standard

Full finger auger standard

Functionality:

A unique feature of the 600R Series Headers is the quick adjustability of the auger in two directions: depth and height. This quick adjustment allows the operator to optimize the header for any crop and condition (for example, set the auger up for harvesting rapeseed) for smoothest feeding, an optimal match for the high performance of the John Deere combines.

Depth and height adjustments

Depth and height adjustments

Full-width auger finger

As mentioned above the 600R Series Cutting Platform augers come standard with full-width retractable fingers. That means the operator must always one additional finger between each wrap of auger flights which helps to move tough or green crop faster and creates a more even feeding. The high-capacity auger is easy to maintain and has a great uptime. Each intake finger can be reached easy and comfortable by special designed service doors on the intake auger to keep uptime high and the harvest efficient. The intake auger position is adjustable for maximum versatility.

Full-width auger finger

Full-width auger finger

Unique John Deere fingers

Unique John Deere fingers

The retractable fingers are 16 mm (0.63 in.) in diameter with a reach of 125 mm (4.9 in.). Fingers have a breakaway groove and are secured with a retainer preventing them to enter on the combine. Replacement is fast and easy.